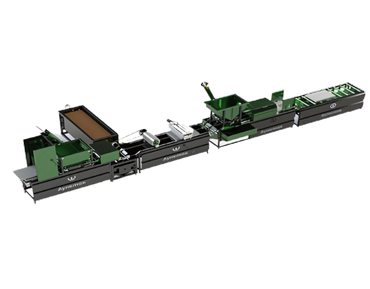

All Features

Empty Tray Feeding System

Driven by the chassis motor, this mechanism automatically replaces used trays in the tray magazine with empty ones. The Empty Tray Feeding system supports fast and continuous production, eliminating the need for additional labor. Unlike imported machines, it provides greater efficiency and lower operational costs, making it an essential component for streamlined workflow.

Tray Magazine

Empty Tray Feeding System

Driven by the chassis motor, this mechanism automatically replaces used trays in the tray magazine with empty ones. The Empty Tray Feeding system supports fast and continuous production, eliminating the need for additional labor. Unlike imported machines, it provides greater efficiency and lower operational costs, making it an essential component for streamlined workflow.

Tray Filling Tank

Featuring a high-capacity peat filling system, this mechanism fills trays evenly with peat, supported by limit switches and optical sensors for precision. Powered by the chassis, it prevents continuous motor operation and minimizes wear. The system, composed of PVC belts and drive gears, operates with a cover mechanism that eliminates the need for an extra motor reducing peat waste and ensuring efficient, controlled filling.

Tray Transfer Auger

Peat Compactor

This mechanism features adjustable cylinders that adapt to the width of the tray, allowing control over the peat compaction density. Positioned after the tray filling unit, it ensures that the peat inside each tray cell is evenly and uniformly compacted, creating an ideal base for precise seed placement.

Peat Compactor

This mechanism features adjustable cylinders that adapt to the width of the tray, allowing control over the peat compaction density. Positioned after the tray filling unit, it ensures that the peat inside each tray cell is evenly and uniformly compacted, creating an ideal base for precise seed placement.

Tray Feeding Mechanism

With its V-shaped design, this system evenly distributes excess peat across the tray surface and returns the surplus back to the feeding tank. Equipped with adjustment mechanisms for different tray widths and heights, it ensures optimal alignment. The integrated mechanical cleaning system removes excess peat from the trays, providing a smooth, consistent surface for the next sowing step.

Pressing Unit

Vermiculite Unit

İthal ürünlerde bulunmayan bu sistem makinanın yüksek hızlarda çalışabilmesi sağlayan alt vermikulit kazanındaki vermiküliti üst vermikülit dolum – kapama kazanına aktarılmasına sağlayan helezon sisteminden oluşur. Vermikülit dolum kazanındaki silo dolum sensörünün yazılımıyla yönlendirilecek helezon motorunun sürekli çalışması önlemiş müşterinin ihtiyaçları doğrultusunda mekanizmalar eklenerek geliştirilmiş sistemdir.

Seed Sowing Unit (DRUM System)

This section, referred to as the DRUM-type seed sowing system, consists of dual comb units, air-blow rods, seed reservoir, seed release unit, vacuum separation system, and servo motor components.

The structural strength has been increased from 2 mm to 30 mm, extending the machine’s lifespan. The improved seed-singulation units enhance single-seed accuracy, while the servo motor system and enlarged drum diameter have doubled the sowing speed compared to imported alternatives.

Vermiculite Unit

After the seeding process, the vermiculite unit completes the planting stage by covering the trays with a balanced layer of vermiculite. The system includes a large-capacity tank and a controlled vermiculite drum for even distribution. The front section is fitted with a transparent mica panel to monitor material levels, and an integrated silo-filling sensorenables automatic refilling.

Designed for high-speed, high-quality operation, this system eliminates the need for extra labor thanks to its wide tank capacity and automatic feeding unit. Adjustable mechanisms reduce vermiculite consumption while improving germination quality and seedling uniformity.

Roller Chassis

Çoklu paketleme imkanı sağlayan istifleme bölümünden sonra dizilmiş ve sıralı gelen viyolleri paketlere aktarılmasını sağlandığı avare rulolardan oluşan geniş hacme sahip bölümlerden oluşur. Viyolleri çimlendirme odasına gönderilmesi öncesi son kalan fazlalık suyun süzülmesi için beklenen, makinanın yüksek hızda çalışmasını sağlayabilmek amacıyla geniş hacimde tasarlanmıştır.

Crusher Unit

The crusher breaks down compressed peat into fine, uniform particles to ensure homogeneous mixing with vermiculite and perlite. It operates via high-capacity blades driven by the same motor as the mixing tank. Unlike imported machines, this system provides superior fragmentation performance and fully meets the needs of professional seedling producers, ensuring optimal substrate consistency for sowing.

Mixer Unit

The mixer consists of a high-capacity mixing auger and humidifying unit powered by its own motor drive. Designed for industrial-scale production, the mixing tank is optimized in length and width to prevent material buildup and minimize waste. It mixes vermiculite, peat, and perlite uniformly before transferring the prepared substrate to the tray filling tank. This system provides a consistent, high-quality growing medium, ensuring uniform germination and healthy seedling development.

Testimonials

Review from Our Customers

Planning

We carefully plan every stage of the sowing process to maximize efficiency and select the most suitable machine for your requirements.

Production

Our machines are manufactured with precision using premium-grade materials to guarantee long-lasting performance and consistent quality.

7/24 Support

We conduct all quality and performance tests after production and offer 24/7 technical support for installation and maintenance.

Our services

Our Machines That Make Your Job Easier